Yuav ua li cas qhov kev kuaj crush ib nrab ua rau lub cell deactivation?

Yuav ua li cas yog ib nrab crushkuaj leadrau cell deactivation?,

kuaj lead,

▍ Daim ntawv pov thawj TISI yog dab tsi?

TISI yog luv luv rau Thai Industrial Standards Institute, koom nrog Thailand Industry Department. TISI yog lub luag haujlwm rau kev tsim cov qauv hauv tsev nrog rau kev koom tes hauv kev tsim qauv thoob ntiaj teb thiab saib xyuas cov khoom thiab cov txheej txheem kev soj ntsuam tsim nyog los xyuas kom meej cov qauv ua raws thiab kev lees paub. TISI yog ib lub koom haum uas tau tso cai los ntawm tsoom fwv rau kev cai lij choj pov thawj hauv Thaib teb. Nws tseem yog lub luag haujlwm rau kev tsim thiab tswj cov qauv, kev pom zoo hauv lab, kev cob qhia cov neeg ua haujlwm thiab kev sau npe ntawm cov khoom. Nws raug sau tseg tias tsis muaj lub koom haum tsis yog tsoomfwv cov ntawv pov thawj hauv Thaib teb.

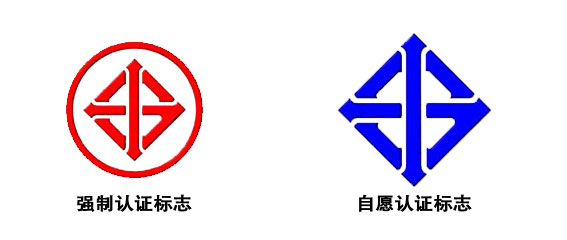

Muaj daim ntawv pov thawj txaus siab thiab yuav tsum tau ua hauv Thaib teb. TISI logos (saib daim duab 1 thiab 2) raug tso cai siv thaum cov khoom ua tau raws li cov qauv. Rau cov khoom lag luam uas tseem tsis tau muaj tus qauv, TISI kuj tseem siv cov khoom sau npe ua cov ntawv pov thawj ib ntus.

▍ Yuav Tsum Tau Certification Scope

Cov ntawv pov thawj yuav tsum tau them 107 pawg, 10 thaj chaw, suav nrog: cov khoom siv hluav taws xob, khoom siv, khoom siv kho mob, cov khoom siv, cov khoom siv, tsheb, PVC kav, LPG gas ntim thiab cov khoom ua liaj ua teb. Cov khoom lag luam dhau qhov peev txheej no yog poob rau hauv daim ntawv pov thawj yeem. Roj teeb yog cov khoom siv ntawv pov thawj hauv TISI daim ntawv pov thawj.

Applied standard:TIS 2217-2548 (2005)

Cov roj teeb siv:Cov xov tooj thib ob thiab cov roj teeb (muaj cov alkaline lossis lwm yam tsis yog-acid electrolytes - kev nyab xeeb rau cov khoom siv sib txuas, thiab cov roj teeb uas tsim los ntawm lawv, siv rau hauv daim ntawv thov portable)

Txoj cai muab daim ntawv tso cai:Thai Industrial Standards Institute

▍ Vim li cas MCM?

● MCM koom tes nrog cov koom haum tshawb xyuas lub Hoobkas, chav kuaj thiab TISI ncaj qha, muaj peev xwm muab cov ntawv pov thawj zoo tshaj plaws rau cov neeg siv khoom.

● MCM muaj 10 xyoo kev paub ntau hauv kev lag luam roj teeb, muaj peev xwm muab kev txhawb nqa kev tshaj lij.

● MCM muab kev pabcuam ib-nres los pab cov neeg siv khoom nkag mus rau hauv ntau lub khw (tsis yog Thaib teb suav nrog) ua tiav nrog cov txheej txheem yooj yim.

Crush yog qhov kev sim zoo heev los xyuas qhov kev nyab xeeb ntawm cov hlwb, simulating kev sib tsoo ntawm cov hlwb lossis cov khoom siv kawg hauv kev siv txhua hnub. Feem ntau muaj ob hom kev xeem crush: tiaj tus crush thiab ib nrab crush. Piv nrog rau lub tiaj tus crush, ib feem ntawm qhov indentation tshwm sim los ntawm ib tug kheej kheej los yog cylindrical indenter feem ntau yuav ua rau lub cell tsis zoo. Lub sharper lub indenter, qhov ntau concentrated qhov kev ntxhov siab nyob rau hauv lub core qauv ntawm lub lithium roj teeb, qhov loj dua lub rupture ntawm lub puab core, uas yuav ua rau deformation thiab txav ntawm lub hauv paus, thiab txawm ua rau loj txim xws li electrolyte to los yog. txawm hluav taws. Yog li yuav ua li cas crush coj mus rau lub deactivation ntawm tes? Ntawm no qhia koj txog kev hloov pauv hauv cov qauv ntawm cov tub ntxhais hauv kev xeem hauv zos extrusion.

Nrog ntxiv compression ntawm lub taub hau crushing, lub deformation yog expanding thiab localization yog tsim. Nyob rau tib lub sijhawm, txheej sib nrug ntawm txhua txheej electrode yog maj mam shortened. Nyob rau hauv tas li ntawd compression, lub tam sim no collector yog khoov thiab deformed, thiab shear bands yog tsim. Thaum lub deformation ntawm cov khoom siv electrode mus txog qhov txwv, cov khoom siv electrode yuav tsim cov kab nrib pleb.

Nrog rau qhov nce ntawm deformation, qhov tawg maj mam txuas mus rau cov khoom siv tam sim no, uas yuav raug torn thiab tsim cov pob txha tawg. Tsis tas li ntawd, lub radial tawg yog elongated vim qhov nce ntawm kev ntxhov siab thiab radial hloov chaw.